Catch up on the latest industry news!

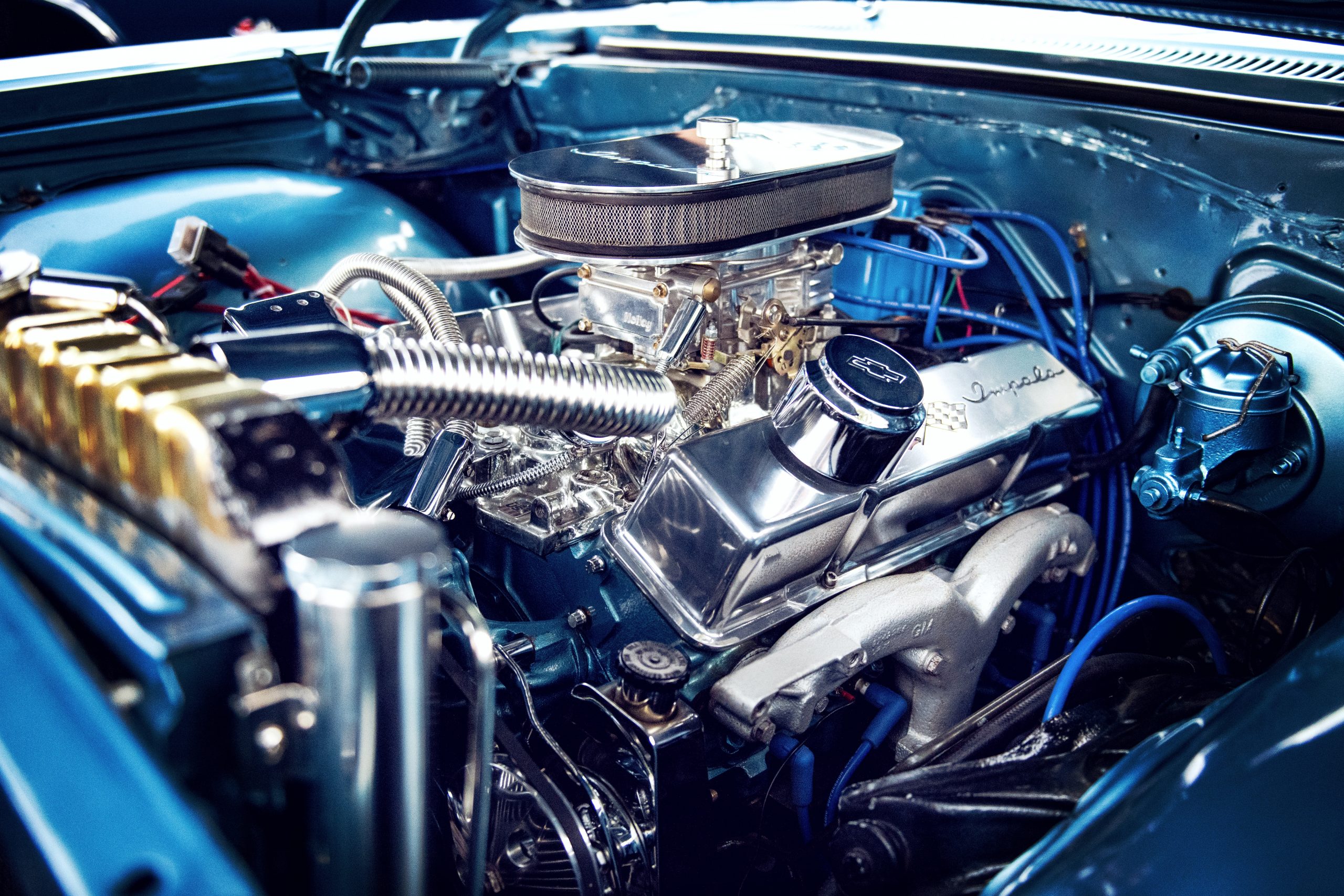

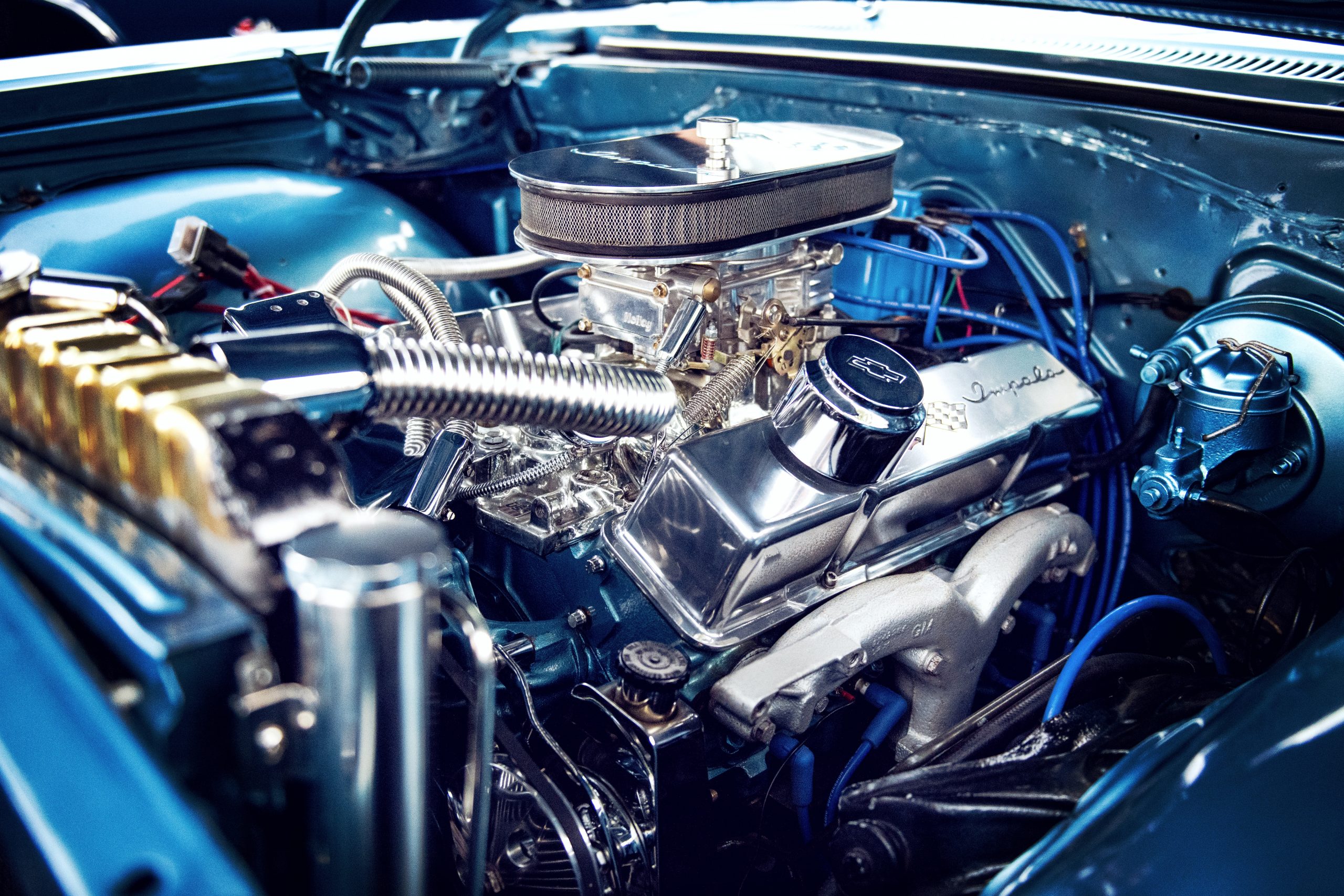

Get the inside scoop on our incredible builds and repair work. Plus review the latest products to hit the market.

Our latest News

Get the inside scoop on our incredible builds and repair work. Plus review the latest products to hit the market.