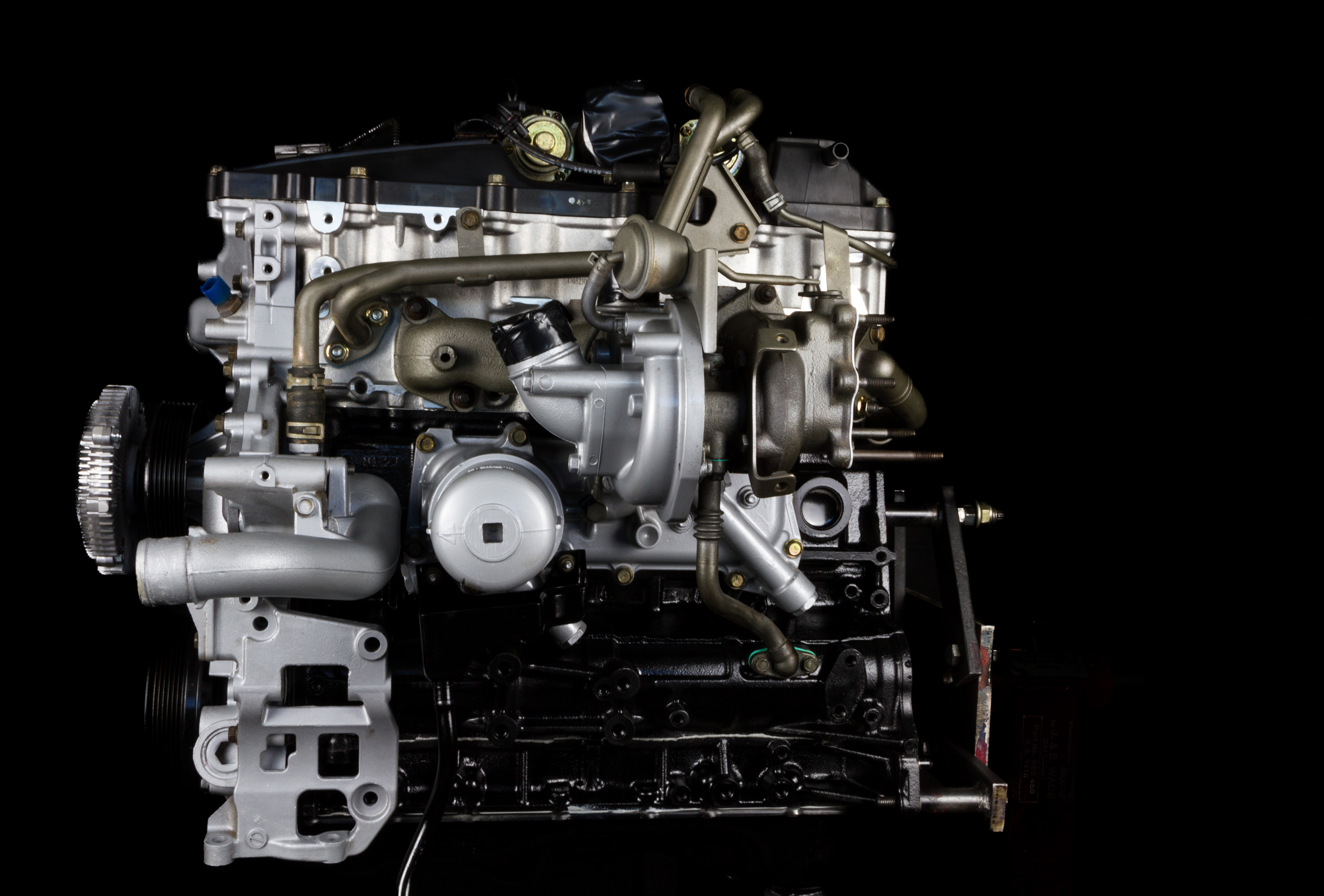

Nissan Navara Engine Rebuild After Coolant Loss

What started as a small coolant issue in a 2004 Nissan Navara quickly turned into a full engine rebuild. This job reminded us how minor warning signs can sometimes reveal major underlying problems—especially when poor fuel quality is involved.

Customer Concern: Unexplained Coolant Loss

A customer brought in their 2004 Nissan Navara, concerned about ongoing coolant consumption—around 100ml per day. Aside from a little smoke on cold starts, the engine seemed to run just fine.

Our first step was to check the cooling system for carbon dioxide, which would indicate combustion gases entering the system—usually from a failed head gasket, a cracked head, or on later models, a damaged EGR cooler. However, this test came back clean, with no signs of CO₂ in the coolant.

Pressure Test Points to Internal Leak

We pressurised the cooling system next. It quickly lost pressure, despite no external leaks. This strongly indicated that coolant was escaping into the combustion chamber. Combined with the slightly rough startup behaviour, we suspected either a cylinder head or head gasket failure.

Engine Removal and Inspection

Due to visible oil leaks from the rear main seal and lower sump, we recommended removing the engine to address both the suspected internal leak and the existing oil issues. The customer approved the plan, and we got to work.

But what we found next was far worse than expected.

Damage Report: Cracked Head, Damaged Pistons, and More

Upon removing the cylinder head, here’s what we uncovered:

-

The head gasket had failed around cylinder four, allowing coolant to contaminate that cylinder

-

The cylinder head was cracked in four places, between each glow plug recess and the adjacent valve

-

Cylinder four showed further damage due to coolant ingress

-

Pistons in cylinders two and three were starting to crack across the crown

-

Pitting and metal splatter was found on the crown of piston three

-

Some of that metal had travelled down the piston’s side, leaving deep scoring in the piston skirt and cylinder bore

It became clear that this repair had now escalated into a complete engine rebuild.

Fuel System Diagnosis Reveals Root Cause

The presence of metal splatter and piston cracking pointed to more than just coolant issues. We suspected a fuelling problem, so we removed the fuel pump and injectors and sent them off for testing.

The results confirmed our suspicions:

-

A failing bearing in the fuel pump had begun shedding metal filings

-

These filings contaminated the entire fuel system, damaging two injectors

-

The bearing failure was most likely caused by water contamination or bacterial growth, as staining was visible inside the pump

The root cause? Most likely poor-quality or contaminated fuel.

How to Prevent Fuel-Related Engine Damage

This failure highlights the importance of fuel quality in diesel engines. At our workshop, we always add a premium diesel fuel additive at each service. These additives:

-

Help clean injectors

-

Reduce the risk of water and bacterial contamination

-

Extend the lifespan of fuel pumps and injectors

If you own a diesel-powered vehicle, here’s how to protect your engine:

-

Always use quality diesel fuel

-

Replace your fuel filter regularly

-

Consider installing a secondary fuel filter

-

Use a high-quality fuel additive every service

Final Thoughts

A small issue like coolant loss or contaminated fuel might not seem like a big deal at first. But left unchecked, it can lead to complete engine failure, just like in this 2004 Nissan Navara.

Don’t wait for warning signs to become catastrophic. Regular servicing, high-quality fuel, and good maintenance habits are the best protection your engine can get.

We weren’t quite prepared for what we found when we took the head off….

• The head gasket had failed around number four cylinder and coolant had contaminated that cylinder

• The head was cracked in four places, between each glow plug recess and the adjacent valve

• There was additional damage to the head on number four cylinder, from the coolant ingress

• Number two and number three pistons were starting to crack across the crown

• There was pitting and metal splatter on the crown of number three piston

• Even worse, some of the metal splatter had worked its way down the side of the piston, leaving deep scour marks in the bore and the side of the piston.

Clearly, what had started as a head gasket had now advanced to a full rebuild. But from the metal splatter and cracking on the pistons, there were also fueling issues that we had to get to the bottom of. So the fuel pump and injectors were removed and sent to the injector experts for testing.

They soon came back to us with the source of the problem. One of the bearings in the fuel pump had started to fail, shedding metal filings inside the pump. These would have circulated through the fuel system, contaminating the injectors, two of which were malfunctioning under testing. And the cause of the bearing failure: either water contamination (there was some water staining inside the pump), or bacterial contamination from the fuel tank. Either way, second rate fuel had probably finished off the engine.

This is why we use a good quality fuel additive every time we service a vehicle at our workshop. Good additives not only clean the injectors, but also reduce the risk of water and bacterial contamination. If you own a diesel powered vehicle, regularly changing your fuel filter and even fitting a secondary fuel filter will all help keep you fuel system, and your engine, in good condition.